Wicks are the simplest and probably most important part of a candle, taper, or any lamp which burns a braid to provide light.

It is the driving force of a candle; the part that causes the burning and which also determines how it will burn and for how long.

For this reason, the wick is probably one of the most important parts, determining the success of the product. At Trenzados José Pla we have worked for over 30 years manufacturing wicks for the most important candle factories. We know the importance of the material, whether cotton, rayon or the most modern materials, so that the final result is of the best quality. Our experience and good work in manufacturing speak for us.

Wicks for the candle factory industry

¿Why choose Mechas Pla?

We are specialized manufacturers

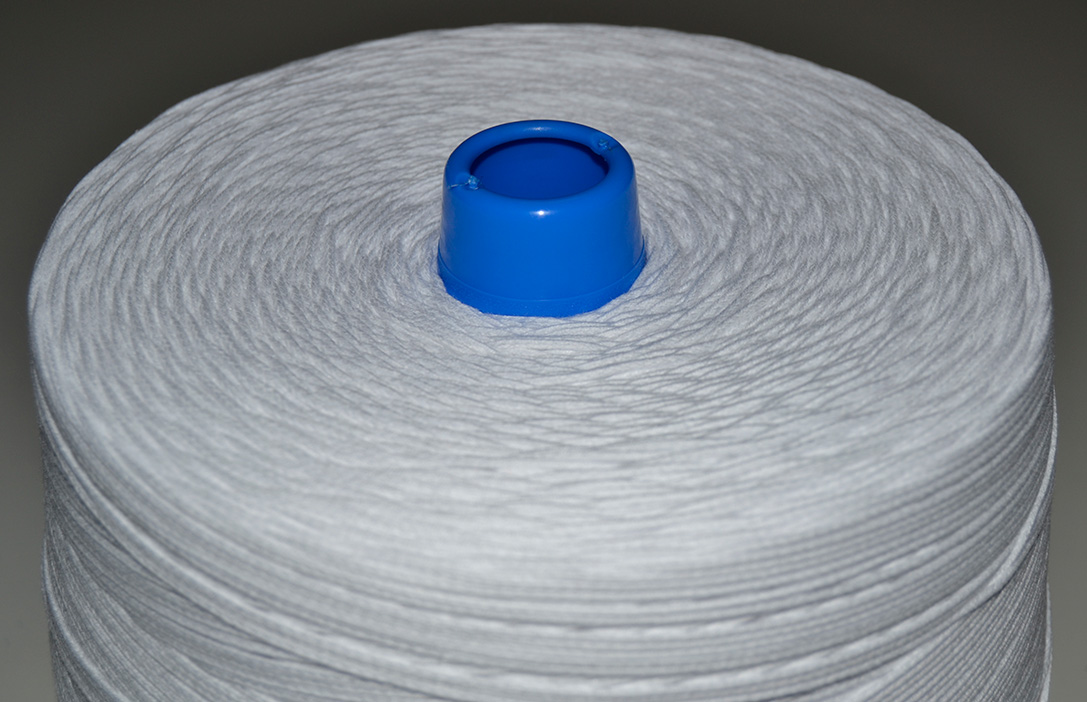

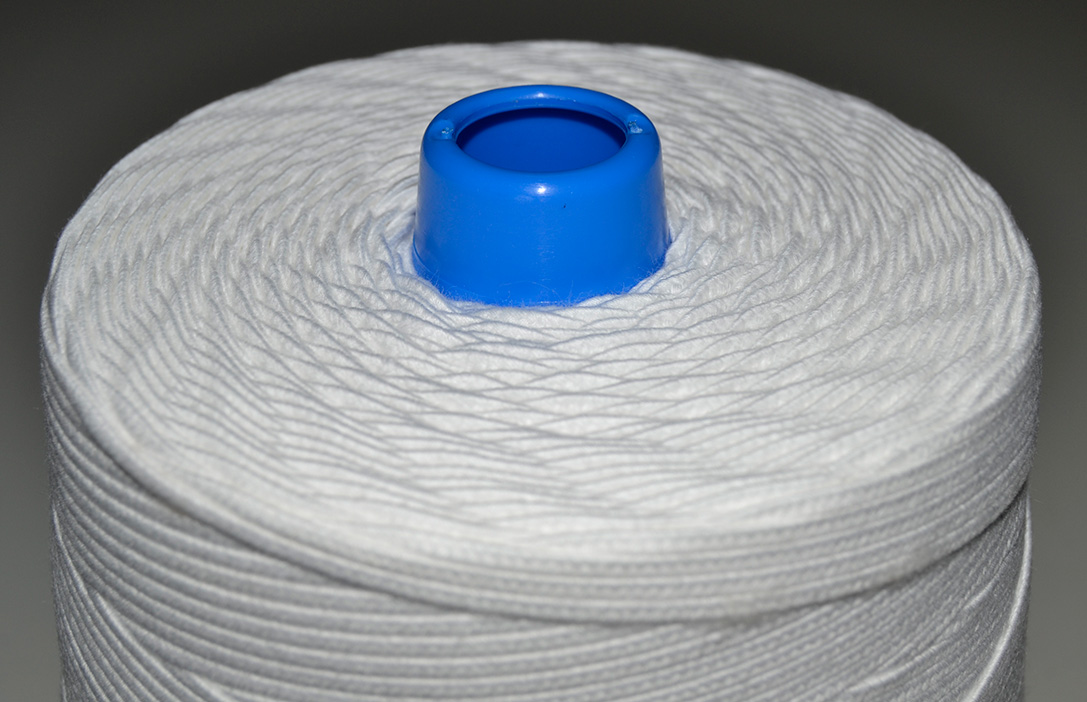

We are wick manufacturers specialized in cotton and rayon. All of these wicks and tapers are produced with years of experience and proper operation in a multitude of designs created by the most renowned manufacturers of the candle factory sector.

Quality in materials

The quality of the wicks for candles begins with the quality of materials and undertaking burning tests to determine that they are optimal for the candle that the factory will manufacture.

Safety in burning

It is not only important to select the wick of the correct size for its best aesthetic appearance and subsequent burning, it is also very important for keeping clients safe and healthy.

CUSTOMISED WICKS AND SPECIALISED CONSULTING

Discover more reasons to choose us

Mechas – Pabilos – Wicks

Where to purchase wicks for candles: how to choose the correct wick

The selection of the correct wick for candles is determined by a process of years of experience and experimentation. Different tests are carried out to rule out potential errors, allowing us to know which braid and which material will provide the optimal results.

Due to the different natures of waxes, from the most traditional beeswax to resins of materials such as soya, and synthetic waxes, and taking into account the various standards of fragrances that are available, we advise the use of different braids and materials.

When we face a new situation, the process is to experiment, test and burn the candle to evaluate its performance and make a decision based on this. After this process, we evaluate results and proceed to manufacturing after approval from the candle factory that the desired quality standards have been fulfilled in terms of durability, capacity for releasing aromas, and proper burning.

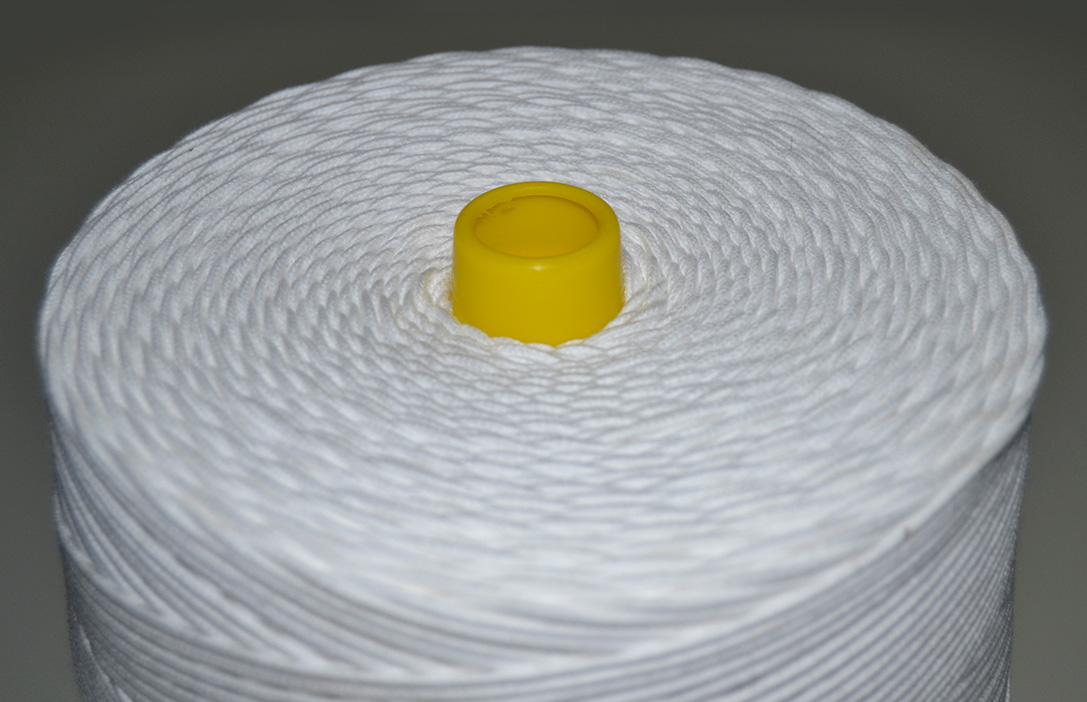

The taper: the part of the wick that is seen

The taper, which may be positioned twisting from the vertical candle, is the part of our braid that everyone sees at the wholesaler. Although it is small, it is very important.

In candles manufactured with paraffin, proper lighting of the taper extremely important. The wick interacts with this material, creating a type of memory, by which a correct first lighting will mean that for subsequent lightings, the candle will function perfectly.

Keeping tapers lit until a small pool of wax is created around it is our advice for all manufacturers and candle lovers.

In more modern materials created with resins of soya or other alternatives, this has minimal importance, but at Trenzados José Pla we are heirs of the manufacturing tradition and take care of our tapers, as in the end they will show our work.